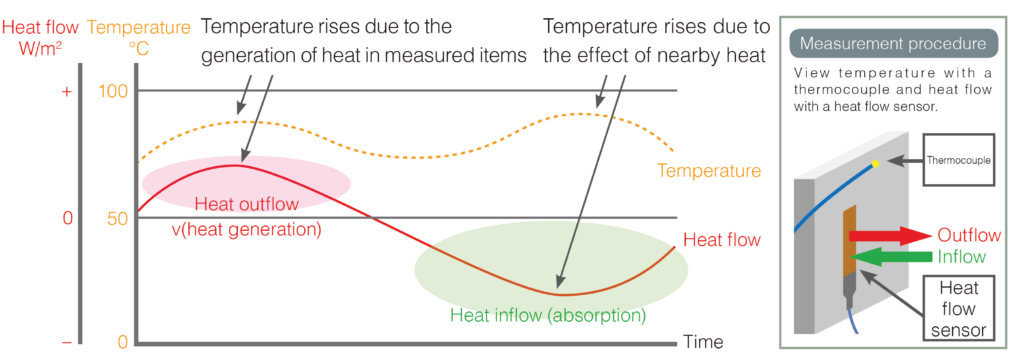

How can heat flow sensing help you to better understand the thermal behaviour of your application? Heat flow measurement helps you to determine the direction and amount of heat that flows through an object and to identify heat sources. This allows drawing conclusions about the source and reasons for temperature changes, and this insight is extremely useful to improve many applications, from battery pack design and component testing to insulation testing for buildings.

The traditional way to measure for example thermal insulation of a building is to use an array of thermocouples and measure the change in temperature under changing conditions: If the outside temperature is low, heat will flow from the inside to the outside and when the outside temperature is high, the heat will flow into the other direction.

Alternatively, you can measure the flow of heat directly by using a heat flow (or heat flux) sensor. This will provide you with interesting insight, like how much heat can your system dissipate at a given temperature. With this valuable information you can judge if the thermal design of your system is sufficient or not.

If your application has multiple heat sources, heat flow measurement can help you to identify the main source and take appropriate actions.

Heat flow sensing in battery and component testing

Not by measuring temperature but also detecting the source of heat development using heat flow measurement can deliver valuable information during the design of EV battery packs where thermal management is essential to ensure safety and a long battery service life.

This method can also shorten the evaluation time of components. Instead of waiting for temperature changes, which are typically very slow, the measurement results of heat flow enable to estimate the result of the test much quicker.

A dedicated instrument: the LR8432 Heat Flow Logger

With the HIOKI LR8432 Heat Flow Logger you can log heat flow when a heat flux sensor is connected. In addition, the compact LR8432 can also log temperature using thermocouples, DC voltage and pulse signals.

The LR8432 Heat Flow logger is based on the well-known compact Data Logger LR8431. The LR8432 offers specific features for heat flow measurement starting with the easy set up of heat flow sensors such as the sensitivity coefficient setting. The logger also offers real time waveform calculation for moving average or integration, double gauges to visualize temperature and heat flow at the same time, and an additional low voltage range of 10 mV, which results in a 10-times better resolution compared to its sibling, the LR8431.

Interested in heat flow logging? Contact us at hioki@hioki.eu

To delve deeper into HIOKI’s Data Acquisition, check out our article on “Wireless data logging for effortless vehicle testing“.

*application picture shows Hukseflux FHF heat flow sensors.

Find more information at the links below.