In less than three seconds it precisely measures the battery resistance at 1000 Hz as well as the battery voltage and it lets you make pass / fail comparisons based on freely defineable threshold values. Depending on the version this tester comes with Bluetooth connectivity to store data in the cloud or wherever you like and depending on the version it also comes with different test leads that are either straight or L-shaped. Alternatively there is a clip type test lead called HIOKI 9460 – this probe has a temperature sensor integrated into the test lead which connects to the temperature sensor input of the BT3554.

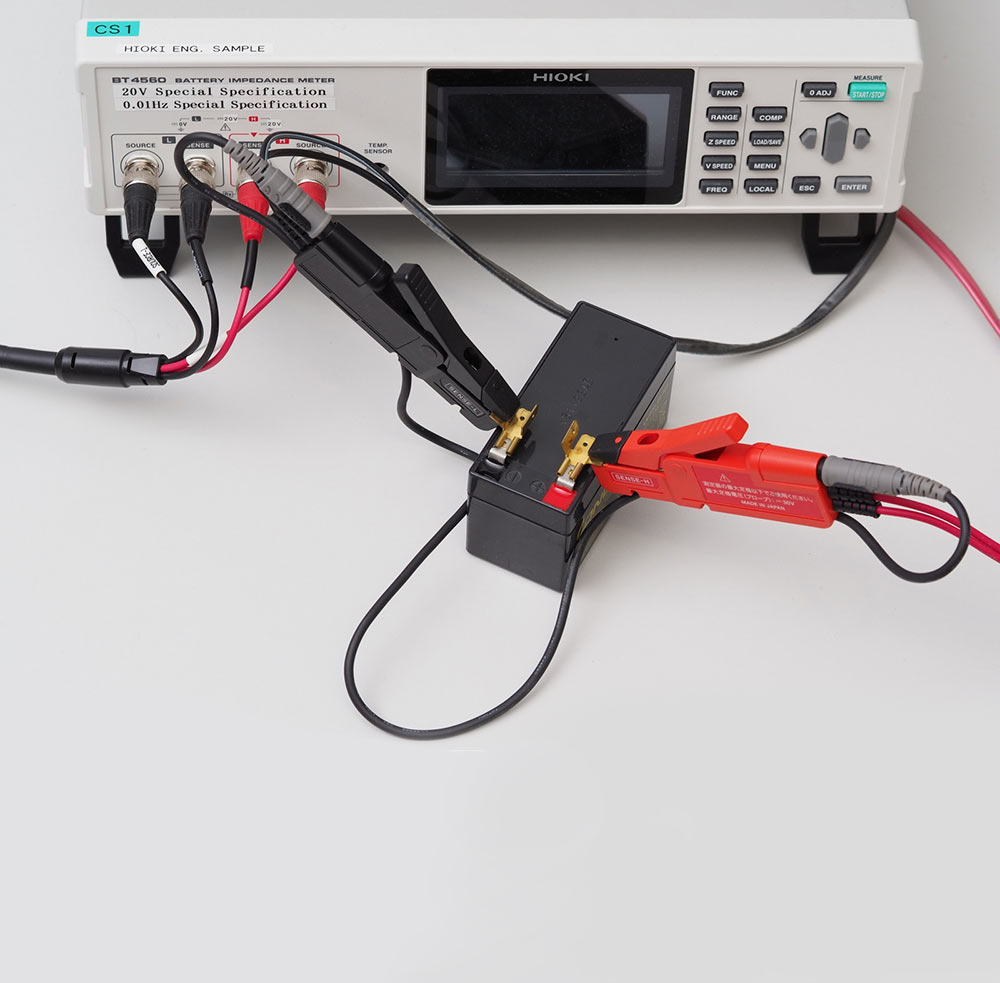

What I wanted to know is how much influence temperature actually has on measurement results of batteries typically measured with the BT3554 and whether it makes sense to have temperature values included when making measurements. Working for HIOKI gives me access to all kind of test equipment because the European demo pool is less than 20m away from my desk. For this test I borrowed a special version of HIOKI’s BT4560 battery impedance meter. “Special version” because this one goes up to 20V while the normal BT4560 only goes up to 5V as this instrument is primarily designed to measure lithium ion cells. The reason why I picked this special version of the BT4560 instead of simply using a BT3554 was because I was curious to see the temperature effect also depending on the test frequency and the BT3554 only has a fix test frequency of 1000 Hz. My test battery was a 12V / 1.2A “rechargable sealed lead-acid battery” called “WP1.2-12” from “Kung Long Batteries” which I happened to have flying around in a drawer of my basement. To be able to connect the probe tips of the BT4560 test leads I “customized” some brass clips that fit the battery connectors. The complete test setup looks like this:

I went for three different test temperatures: Room temperature at around 20°C, fridge temperature at 6°C and freezer temperature at around -18°C. By the way, I am not sure how to read it when the wife opens the fridge door in the morning to find a lead-acid battery between the joghurt and the jam and there is absolutely no expression of surprise or any “request for comment” at all. Either she is used to things like that after being married to a tech nerd for almost 20 years or she wasn’t quite awake yet. Probably it was something in between…

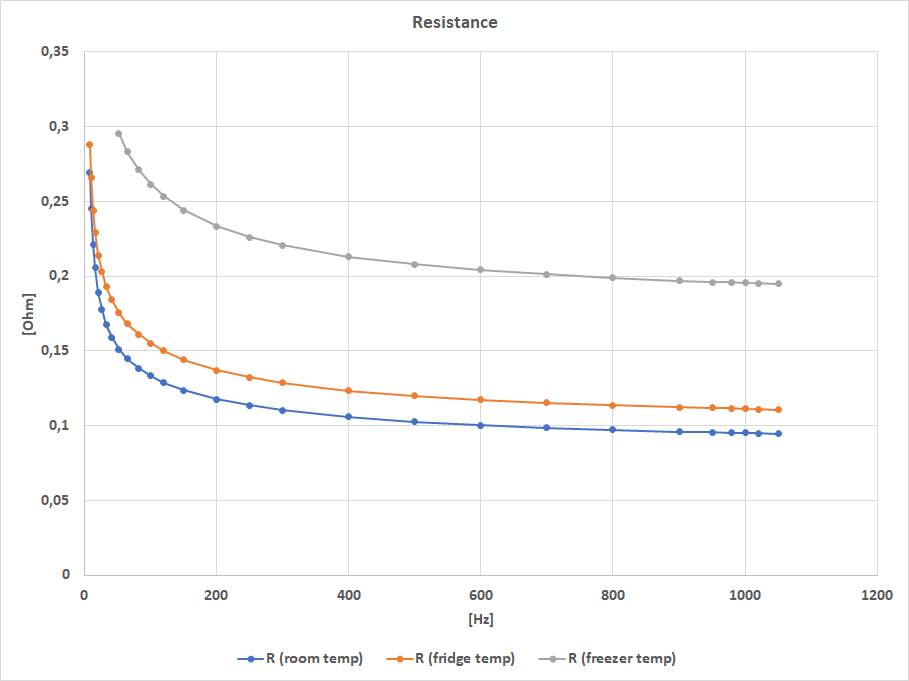

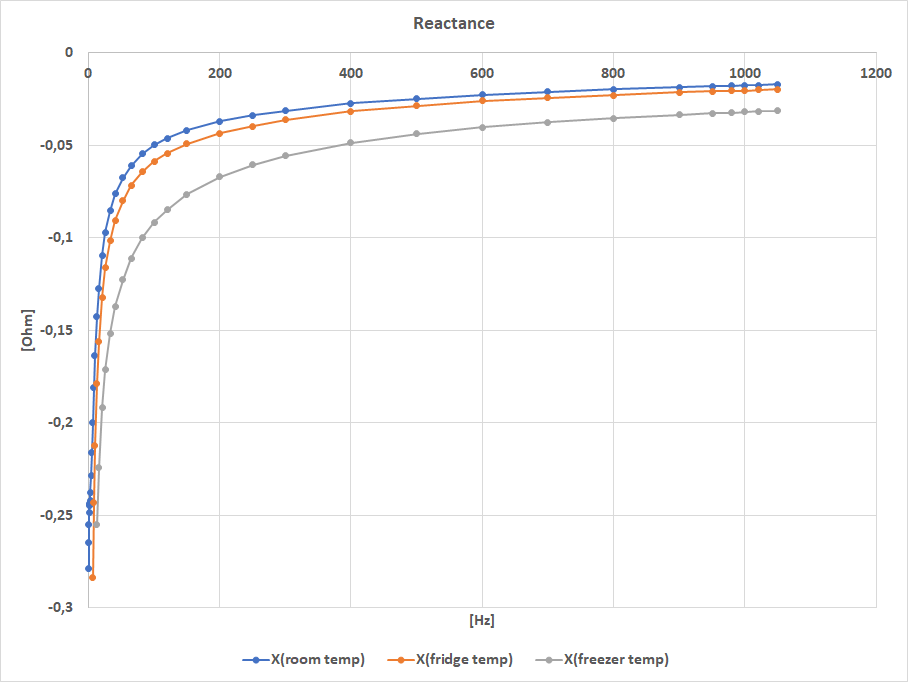

Anyway, I chose around 50 test points between 0.1 Hz and 1050 Hz. The usual output of such a measurement with the BT4560 would be a Nyquist or Cole-Cole plot (two names for the same thing – Nyquist is more common in the Western world, Cole-Cole is more common in Asia) but after exporting the data into Excel I decided to seperate resistance and reactance values to generate two seperate graphs. Lets start with the resistance values:

As you can see I removed all measurement values from the graph that exceed 0.3 Ohm. I’ve done this purely to make the graph more readable because the closer the frequency gets to 0.1 Hz the more the values take off. The resistance at room temperature measured at 0.1 Hz was 0.92 Ohm. at fridge temp it was 1.62 Ohm and at freezer temp I wasn’t able to get a reading because the maximum range of the instrument is 3 Ohm and the measurement was “over range”. Here are the reactance values:

Again, to allow for a better readability I have also eliminated all values from the graph where the reactance value is below -0.3 Ohm. When you compare both graphs I think it becomes pretty clear that looking at reactance values of a lead-acid battery doesn’t provide too much extra information in addition to the resistance values. Also when you look at the resistance values of the three graphs at 1000 Hz then you can see that the ratio of the values is not that much different at 20 Hz or 200 Hz. So there is nothing you really miss when measuring a lead-acid battery only at 1000 Hz which is also the typical value for the ACIR (AC internal resistance) specified for batteries.

As you can see from the resistance graph the values at freezer temperature (-18°C) are around twice the values of those at room temperature (20°C). With that in mind I think it absolutely makes sense to include temperature measurements when using the BT3554 unless the batteries you measure are always in the same temperature environment. If your battery type or your setup doesn’t allow for the clip type sensor HIOKI 9460 to be used which has an integrated temperature sensor or if you simply prefer the straight or L-shape leads then the alternative is a separate sensor called HIOKI 9451S.

A little word of caution regarding these test values:

The battery I used was a rather small lead-acid battery because I needed something to fit into the fridge and the freezer. This means that the measured values are higher than those you can expect from a more typical, larger lead-acid battery because the larger the battery capacity the smaller the battery resistance. Also I have no exact idea about the state of health of this specific battery because it is a couple of years old and it did spend a lot of time in a drawer being unused – which is not the best way to treat a lead-acid battery. So any other battery might very likely show different values and the ratios between the three temperatures may also vary.

Explore our article “HIOKI and Lithium Ion Batteries” if you’re curious about battery testing